A long time ago I studied Food Technology in Wageningen. I mixed the curriculum with a minor in Informatics. When it was time to get a job I chose IT and I didn’t do anything with my Food background. Instead I programmed, managed projects, did Agile coaching. In general I liked to improve stuff and make everything work better.

But last year -by coincidence- I got back into the Food vertical. And surprisingly not because of my academic knowledge on Food Technology but because I became good at doing workshops to rapidly design products. And that works in food just the same. Let me share what I learned by going back to my old industry.

What I – with my digital mindset – have learned looking at Food Innovation

When I say digital I mean Information Technology. And IT came a long way. Do you remember the first ‘smart phone’, or how you had to reboot your computer every hour or two to speed it up? The BSOD from windows 95 still haunt me in my dreams. Software was expensive, a pain to install and difficult to use. But that is all long gone. Apps are now cheap, intuitive and stable.

Not only did the digital products itself improve. The proces to create them improved. Code is now often Open Source, examples on the internet, development done in an Agile way of working. And the proces keeps improving. I see this as a big driver for the better quality. And it makes that small teams create killer solutions. Like this guy created a game that makes $50.000 daily in just 1 week.

So back to my findings.

1. Digital is more progressive

Not a big surprise, I find digital to be more progressive. Of course, it’s a younger industry, but the dynamics are fundamentally different.

The cost of scale for digital products is very low. Whether you have 100 or 10M users on your new app, cost don’t change much. At the other hand, to product 100 or 10M packs of potato salad is a whole different ball game.

If you make food products you take part in a larger and heavily regulated chain. The effort and cost to create new products are high. It requires new production facilities, ingredient sourcing, packaging. Of course the product should be safe, and labels and claims should be correct. The barcode should be registered. And you should buy retail shelf space and run ads.

2. Food industry moves slower

The pace in the Food industry is different. Mainly because it are larger corporations, which are slower by design. But the amount of dependencies of projects are larger. And the more dependencies, the slower the progress. I really learned in order to move fast, make small dedicated teams.

3. No validation

Many food products are launched without clear indications for success. Big decisions are made based on personal opinions of key stakeholders or generic market insights. And this is only more remarkable because of the high introduction cost.

In digital this is really not done, where testing and validation of assumptions has become the new normal. Especially the larger and really successful online companies (the likes of Booking.com) test and optimise everything in and out before changes are made.

4. Little disruptive innovation in Food

There is innovation in Food Technology. But I see little disruptive innovations. The exception may be the current move to plant based proteins.

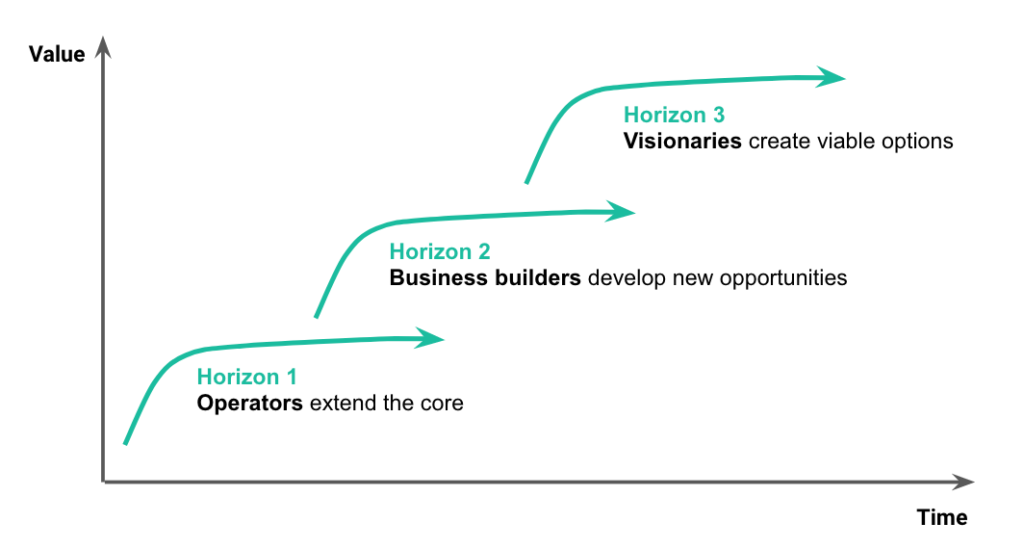

Many new products are line-extensions, me-too products or efficiency improvements. I still like to use the tried and tested 3-horizon model from McKinsey. It classifies types of innovation. Where H1 are line extensions (“New flavour!”) and H3 are the truly disruptive, market creating products (lab grown meat). I know Steve Blank argues the model is broken as today disruptions can be done as fast as smaller innovations. Still the classification itself is very useful.

In digital product teams I tried to split development time between Horizon 1, 2, 3 as 70-20-10%. I see in Food nearly all innovation is H1.

Well, now what?

To stay relevant as a Food company you need truly new products, not just line extensions. Maybe even more than before. And I believe that most new food products are not enabled by new technology. Rather the market demands and consumer needs determine success of your product.

In my next article I’ll share how I do short, intense workshops to create the right product for your consumers, and faster than I thought was possible.

Often used for digital products, but just as effective for Food. And you can do them too!

Hi, I’m Aart. I run Design Sprints and custom workshops to rapidly design food concepts and validate them with consumers. In 1 week and with absolutely no need to build factories beforehand.

Hungry for more? Join my meetup group, get Design Sprint training, let’s have a virtual coffee or find me on social media.